Demonstrating Green Building Leadership

Investing in green buildings demonstrates our firm commitment to environmental sustainability in the real estate sector. In response to escalating environmental challenges, we integrate climate-resilient features, energy-efficient systems, and biodiversity-conscious elements in our buildings in the early-stage design.

Key Performance Indicator (“KPI”) for FY2024/25

90%

Of existing buildings to obtain green building certificates

Performance

97.5%

Of existing buildings with green building certificates1

Our Commitment to Development

100%

New development and asset enhancement project to receive BEAM Plus Gold or above

100%

New commercial, retail, residential/ service apartment development to receive WELL Gold or above

Our Achievements2

18

BEAM Plus certifications obtained for 11 development projects and five asset enhancement projects

3

LEED certifications obtained for two development projects

1

China Green Building Label (“CGBL”) building

8

WELL certifications obtained for six development projects and two asset enhancement projects

1

Building certified with WiredScore, and one building certified with SITES

1 Green building certificates include BEAM Plus/ LEED/ WELL, etc., and the percentage covers the number of certified existing buildings as of 30 June 2025.

2 Covering Registered, Provisional Assessment, Pre-assessment, Pre-certification, and Final Assessment in green building standards as of 30 June 2025.

Green & Innovative Building

Sustainable building is a key aspect of the Group’s sustainability strategy. We have adopted green building principles across the design, construction, and operational phases of property development and management. We prioritise energy and resource efficiency to minimise our environmental footprint and improve occupants’ well-being.

Our Sustainable Design and Procurement Manual provides detailed guidelines for the property development lifecycle, with a focus on design and construction. CCG uses pre- qualification and qualification assessment checklists, built in collaboration with consultants, contractors, and suppliers, to prioritise tenderers who demonstrate strong sustainability practices. With our commitment to innovation and collaboration, the Group is pursuing cutting-edge, sustainable technologies across our designs, products, and services to achieve carbon neutrality. We use the following assessment criteria with an incentive and penalty mechanism to ensure the compliance of awarded tenderers during the project cycle:

- Job experience and references for sustainable building design/construction

- Establishment of an Environmental Policy

- Prohibition from using deleterious building materials

- Building Information Modelling (“BIM”) application capability for reducing waste

- Construction waste management proposal

- No involvement in environmentally-related litigation or arbitration cases

The Sustainable Design and Procurement Manual includes key performance indicators (“KPIs”) for new development and major asset enhancement projects, such as energy performance that fulfills Zero- Carbon Ready Building Certification, a climate risk screening study, and embodied carbon disclosure by main contractors. For details about the carbon accounting approach of embodied carbon, please refer to the “Carbon Footprint Management” section in this report.

Embracing Innovation & Sustainable Construction Practices

To showcase our environmental stewardship, we harness various technological innovation throughout the project lifecycle and advocate sustainable construction practices in construction projects wherever feasible.

Sustainable & Wellness Designs

Smart Internet of Things (“loT”) Systems and wellness designs aim to enhance operational efficiency and safeguard the well-being of occupants. These features are proactively integrated across CCG’s projects.

Smart loT Systems

Smart loT systems use interconnected devices and sensors to collect and analyse data in real time. These systems track energy consumption, environmental conditions, and workers’ safety. By integrating data into a central platform, we can make informed decisions, optimise resource allocation to reduce carbon footprints, and achieve substantial energy savings.

For instance, Nina Hub incorporates smart loT systems to monitor, manage and maintain energy performance. The adoption of Artificial Intelligence (“AI”) optimisation is expected to achieve a 10% energy saving by enhancing chiller efficiency and a 20% improvement in labour efficiency in facility management.

Wellness Designs

We incorporate a range of wellness designs, including smart car park management systems, access control system, AI-powered video analytics for Closed-circuit television (“CCTV”), and UV-C sterilisation, all aimed at enhancing safety, improving air quality, and reducing the risk of illness, thereby safeguarding the well-being of occupants and fostering a healthy environment for our stakeholders.

Sustainable Construction

With low-carbon construction as a top priority, CCG applies sustainable construction practices to enhance quality control, shorten construction periods, and reduce waste and environmental impact.

Modular Integrated Construction (“MiC”)

MiC begins with the off-site prefabrication of entire building modules, which are then transported to the construction site for final assembly and integration. It emphasises standardisation and repeatability, enabling consistent quality and a faster production period. It also promotes innovative design flexibility, allowing for customised solutions while maintaining the benefits of off-site construction.

We observed remarkable advantages of adopting MiC, including a reduction in carbon emissions, an improvement in the working environment and site safety, and an enhancement in construction quality.

Application in:

- ECHO HOUSE at Tonkin Street

- Tung Chung Traction Substation Residential Development

The anticipated carbon reduction for Tung Chung Traction Substation Residential Development project contributed by the adoption of MiC is as follows:

Estimated Carbon Reduction

5,182tCO₂-e

= 377Hong Kong’s standard household’s annual carbon emissions

Multi-trade Integrated Mechanical, Electrical, and Plumbing (“MiMEP”)

MiMEP is an innovative construction approach where mechanical, electrical, and plumbing systems are prefabricated off-site in a controlled environment and then transported and assembled on-site. By simplifying product design to enable efficient manufacturing and assembly, we can save 30-50% of construction time, reduce waste and improve quality control throughout the building process.

Application in:

- Tung Chung East Commercial Development

- Kwai Chung Logistics Centre

- Tung Chung Traction Substation Residential Development

Building Information Modelling (BIM)

BIM enables to generate and manage building data throughout the building lifecycle. Modelling can help us facilitate better decision-making by providing access to real-time data with Building Management System (“BMS”) and Digital Twin during building operation.

Application in:

- Tung Chung East Commercial Development

- Kwai Chung Logistics Centre

- Tung Chung Traction Substation Residential Development

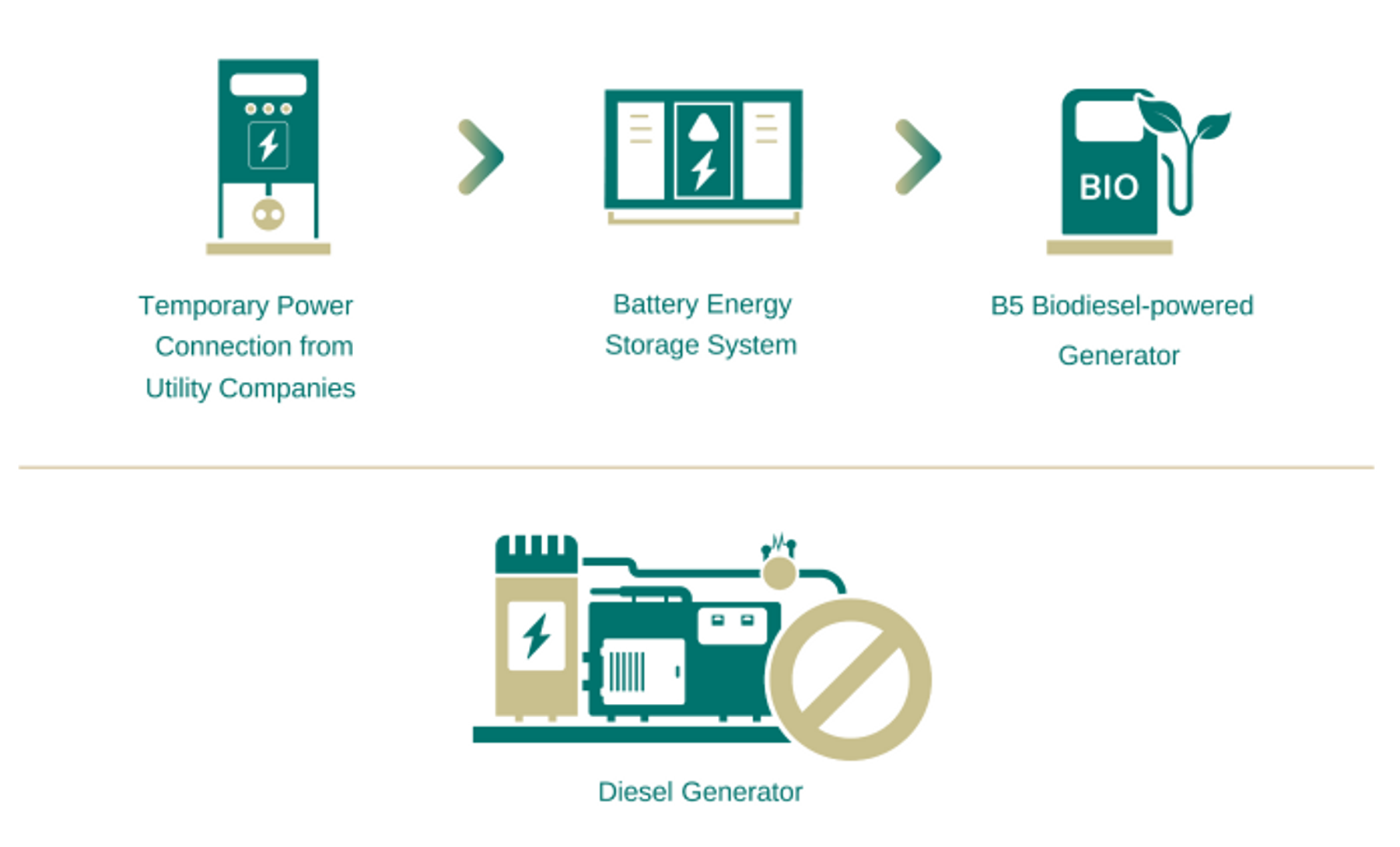

Traditionally, construction sites rely heavily on diesel fuel for temporary power supply during the construction phase. However, we are phasing out the use of diesel generators at our construction sites. We require our foundation and superstructure contractors for new development projects to obtain power directly from utility companies via the electricity grid, thereby achieving electrification at the early stages of construction.

If accessing the electricity grid is not feasible due to site constraints, or higher output current is required, a battery energy storage system (“BESS”) is adopted as “Power Amplifier”, which enables cyclic energy storage and conversion to deliver high-power output for equipment operation. The B5 Biodiesel-powered generator, which uses 5% biodiesel and 95% conventional diesel, is the final resort.

Case Study

Strategic Partnership for MiC with GMC Grand-Bay Intelligent Manufacturing and Technology Co., Ltd

The Group signed a Memorandum of Understanding (“MoU”) with GMC Grand-Bay Intelligent Manufacturing and Technology Co., Ltd. (“GBIMT”), a market leader in prefabricated buildings in the Greater Bay Area and Guangdong Province. The MoU is to establish a strategic partnership for the development and use of the MiC system. Through knowledge exchange in technological innovation, materials procurement, and supply chain management, we aim to collaborate to maximise construction-related carbon emissions.

This partnership delivered the MiC solution for ECHO HOUSE at Tonkin Street, the first high-rise residential project in Hong Kong to utilise a concrete MiC system by private developer. The project adopted digital construction and other technologies.

Tung Chung East Commercial Development

This project is located on the northwestern coast of Lantau Island in Hong Kong. The mixed-use development comprises two towers, including one for office and retail use, and the other for a cutting edge data centre, creating a hub that unites buinsesses, lifestyle, and technologies.

Sustainable Construction Methods

- BIM

- MiMEP

Energy Efficiency

- Digital twin pilot to monitor and optimise the energy efficiency and healthiness of the building and facility management systems

- District cooling system to improve energy efficiency, reduce refrigerant usage, carbon emission and acoustic nuisance

- Electrically commutated plug fans to improve energy efficiency, lower operating costs and achieve quieter operation

- Annual energy utilisation index of 76kWh/internal floor area in m2 (IFA) for the landlord portion of office area, 31% lower than the Hong Kong SAR Government’s Electrical and Mechanical Services Department (“EMSD”)‘s benchmark for Grade A offices

- Photovoltaic (“PV”) solar panel renewable energy generation

Building Certifications

BEAM Plus New Buildings v2.0 |

Provisional Platinum

BEAM Plus New Data Centres v1.0 |

Provisional Platinum

LEED v4 BD+C: Core and Shell |

Pre-certification Platinum

WELL Building Standard™ |

Pre-certification Platinum

- Target to receive Platinum rating WiredScore and SmartScore certifications from WiredScore, which assesses the smart capabilities of a building

Waste Management

- Utilisation of construction Industry Council (“CIC”)’s Smart Waste Management Tool for effective management of construction waste

Wellness Design

- Integration of natural lighting across indoor and outdoor spaces

- Skygarden to provide a tranquil escape from the tense workplace environment and boost social interaction

Accessibility

- Inclusion of street-level stairways and walkways, as well as an elevated pedestrian bridge

Kwai Chung Logistics Centre

This project is designed to incorporate a range of sustainable features, aiming to become the greenest logistics centre in Hong Kong. It has integrated energy, water, and waste management to achieve sustainable site planning and design.

Sustainable Construction Methods

- BIM

- MiMEP

Building Certifications

Hong Kong’s first and only logistics centre to achieve:

BEAM Plus New Buildings v2.0 |

Provisional Platinum

LEED v4 BD+C: Core and Shell |

Pre-certification Platinum

Waste Management

- Utilisation of CIC’s Smart Waste Management Tool

- Provision of food waste and waste compactor, as well as smart recycling bins

Wellness Design

- Design to provide 30% green space

- Target to achieve excellent level in Indoor Air Quality Certification Scheme of the Hong Kong SAR Government’s Environmental Protection Department (“EPD”)

Renewable Energy

- Adopted B100 Pure Biodiesel-powered generator

- Target to generate more than 300,000 kWh of renewable energy annually through a 2,000m2 rooftop PV system

Supporting Facilities

- Over 300 electric vehicle (“EV”) charging points

Tung Chung Traction Substation Residential Development

This project is located in eastern Tung Chung New Town. It features two towers with 1,982 residential units on a podium. This project is the largest MiC residential development project by a private developer to date.

Sustainable Construction Methods

- MiC

- MiMEP

- BIM

Building Certifications

BEAM Plus New Buildings v2.0 | Provisional Platinum

WELL Building Standard™ | Pre-certification Platinum

Water Management

- Low-flow water fixtures to irrigate local plant species with drip-pie and timer control, saving water equivalent to 65 Olympic-size swimming pools annually

- Dual-flush toilet design

- Twin-tank design for potable and flushing water

Waste Management

- Utilisation of CIC’s Smart Waste Management Tool with substantial reduction of 15% construction waste

- Provision of waste compactor, and smart recycling bins, reducing waste generation during building operation phase

Green Construction Materials

- Sustainable timber products for temporary construction works

- At least 10% recycled material used for exterior surfacing works

- Green concrete to reduce 28,503 tCO²e of carbon emissions, achieving the reduction of embodied carbon intensity to 787.48 kg CO²e/construction floor area in m2 (CFA), more than a 21% reduction compared to the baseline of the Hong Kong Green Building Council (“HKGBC”) Climate Change Framework for Built Environment

- Adoption of at least 20% of regional material for building materials, to reduce the environmental impact of transportation and to support the local economy

Energy Efficiency

- Highly energy-efficient air-conditioning combined with a BMS and various sensors, expected to save approximately 3,000,000 kWh of energy consumption annually

- Smart and IoT systems for real-time monitoring

- Solar-powered smart lampposts

Sustainable Site Planning & Design

- 15-meter-wide gap between two residential blocks to enhance air ventilation and facilitates wind penetration

- Balance of air flow with noise reduction for better acoustic treatment

We also enhanced six of our existing buildings to achieve the Platinum level of BEAM Plus Existing Building Standards – Comprehensive Scheme, including:

These enhancement projects generally focused on retrofitting and upgrades that significantly enhance energy and water efficiency:

Lighting

- Replace with LED bulbs

- Install automatic sensor lighting

Water

- Install automatic sensor faucets

BMS

- Monitor and optimise the energy system

Air Conditioning & Chillers

- Equip variable frequency drives in the central air-conditioning system

- Replace both water- and air-cooled chillers

Case Study

Supporting My Green Space Student Competition by Hong Kong Green Building Council

HKGBC partnered with CCG to organise a student competition themed “My Ideal Green and Smart City”. We supported students from local primary and secondary schools, as well as tertiary students from institutions across Hong Kong and the Greater Bay Area, in reimagining urban spaces through smart, sustainable, and people-centric design.

To enhance participants’ understanding and inspire new ideas, we hosted green building tours at our headquarters office in Nina Tower, Nina Park, NINA MALL and Nina Hotel Tsuen Wan West, offering firsthand exposure to sustainable buildings and wellness-focused practices.

Following the tours, students worked in teams to develop and submit innovative proposals. Award-winning teams will showcase their works in a public exhibition and share their experiences during the award ceremony, celebrating their creativity and vision for a greener future.

Competition Highlights:

>500 participants from 82 local and Greater Bay Area schools

> 10 green building tours organised at CCG properties

> 300 students, families and teachers attended